Formula SAE

Steering Team Lead

Founding Member

The apex of design, engineering, & technology

In the spring of my sophomore year (2019), I became captivated by by the innovation and precision of Formula One racing after watching the Netflix documentary series. Realizing that my engineering studies could translate that passion into real-world application, I joined a group of students who were developing Northeastern University's first Formula SAE team.

That year we set out to build the first-ever iteration of our car.

Jumping in at the beginning came with its own set of challenges: we were starting from scratch. As a founding member, I helped with fundraising, recruiting, and marketing in addition to my engineering work. Fueled by excitement, I was ready to apply every facet of my skillset to help this team achieve success.

Steering Lead

Spearheading the design and manufacturing of the car's steering system

PROBLEM

As Steering Team Lead, I spearheaded the design, development, and manufacturing of our vehicle’s steering system. This project had a few unique obstacles which translated to constraints.

Main constraints:

1. Shallow funds

2. Fixed geometry set by preexisting systems

3. FSAE rules

4. Limited personal understanding of vehicle dynamics

After reading the relevant material, I decided that the tight budget was the most restrictive so I gave it the most weight when working on my design.

ACTION

1. Salvaged a legacy rack and pinion system

- I decided to salvage a rack and pinion system that I had available to me from a go-kart that the club had disassembled.

- Benefits:

1. free initial cost

2. existing size was relatively similar to the geometry I needed.

3. Minor manufacturing adjustments

The main benefits of this decision are listed above. Manufacturing would include minor changes to the existing system, fabrication of mounting fixtures, and supporting parts. Since my team and I would be doing a majority of the manufacturing in-house, the overall costs will be very low.

2. Identify geometry based on existing constraints

To identify any changes that needed to be made, I took a series of measurements including knuckle location and the area of the nose of the car. These parameters set the position of the steering rack.

Next, I identified the position and orientation of the steering wheel. With these sets, I took a step back to look at the steering system in position. I realized that the initial steering column length set the Universal joints at an angle that was too steep. Knowing that U-Joints translate torque best at an angle greater than 160, I decided that I needed to shorten the length of the steering column by removing some material from the middle.

3. Measure and manufacture changes

I measured it to the appropriate length using Solidworks, then I took a Sawzall and made two cuts to remove a piece from the center of the shaft. I knew that this would serve as a weak point for the column so I designed a structural brace to wrap around the seam.

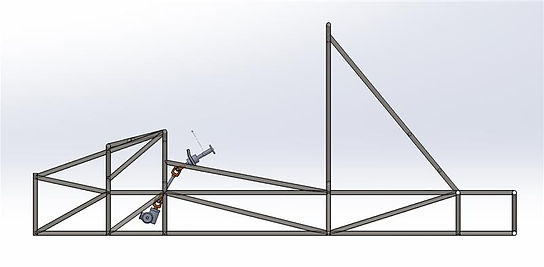

Figure 1. Existing Rack and Pinion in Chassis

Figure 2. Measurements taken from front suspension SolidWorks model

Top Mount

PROBLEM

Design constraints:

- dashboard geometry

- weight and position of the steering column

- 2 important FSAE rules.

- manufacturability

Below are the specific FSAE rules that governed my design and are they are visualized by the red and yellow lines in Figure 4.

FSAE Rules

T.1.6.8: In any angular position, the top of the steering wheel must be no higher than the top-most surface of the Front Hoop.

T4.8: Driver Egress All drivers must be able to exit to the side of the vehicle in no more than 5 seconds.

Based on the first rule, I knew that the height of my steering wheel would be limited by the front hoop. Additionally, the second rule limited the angles from which I could mount my steering wheel. If I were to mount the steering wheel from the side of the frame it would interfere with the driver's ability to escape. As a result, I would have to mount my design to the front hoop.

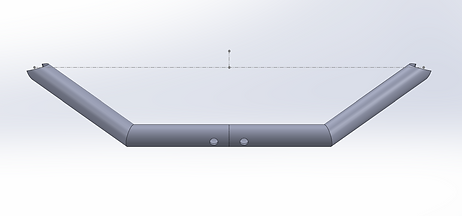

My design utilized a trapezoidal geometry with two angled holes on the front. The ends of the fixture were to be welded onto the chassis. Initially, I had miter joints connecting the side pieces to the center, but I realized that they were not essential to the design so I replaced them with a square cuts pipe to simplify the manufacturing process.

ACTION

Manufacturing

The mount was fabricated from 3 pieces of 1-in steel pipe (95 thousands thick). I chose this material because our team had this stock pipe available to us in abundance and it was the same pipe that the chassis was made out of. The likeness of these two materials would allow for a very easy weld process to join the mount to the chassis.

I decided to fabricate these parts using a tube notcher, angle grinder, and welds to join the pieces together. I decided to make a flat pattern to help guide me.

Here is an outline of my process:

-

Model notched tube in Solidworks

-

split the model down one side and "unwrap" it

- print a 1:1 scale drawing

-

cut the tube to the specified length

-

cut the pattern out and tape it around the tube

-

Use tube notcher to create the desired shape

-

Use an angle grinder to clean up the edges

Welding Process

-

Clean the pieces

-

Arrange them on a jig with a 1:1 scale print

- Tack weld into place to hold the tubes in the proper alignment

-

Weld small lengths of the joints alternating sides to account for any warping

-

Visually inspect the weld for cracks or gaps

-

Look through the square-cut joint for heat discoloration to ensure full penetration

Figure 4. FSAE rules regulating steering system

Figure 5. Flat pattern for top mount component

My Process

Figure 3. Model of top mount

Figure 6. Me doing some practice before welding the top mount together

Results

The slideshow below contains images of the car and steering system development. In my time as Steering Lead, we were able to complete 80% of the manufacturing. However, our time was cut short when we began remote learning due to the pandemic. In these past few months, I have been working with new team members to improve the design. Our goal is to be ready for competition in 2021!

Below is a series of images of the steering system, our car, and the team!